"If you can’t measure it, you can’t improve it."

There is usually no silver bullet for saving energy – it’s lots of incremental changes that add up to a sizable gain. An Optima M&T programme is the best way to identify and implement the maximum amount of savings opportunities available in your business.

We scope your situation using leading edge metering technology, analyse the granular data collected to diagnose the causes of wastage and inefficiency, offer technical advice, and create a plan to help you reduce energy costs.

We work in partnership by giving you ongoing access to the data, and providing the tools to detect adverse events and trends, advisory services and practical technical support during the term of your contract with us.

This way of working means you get flexible, bespoke and valuable solutions at a lower cost.

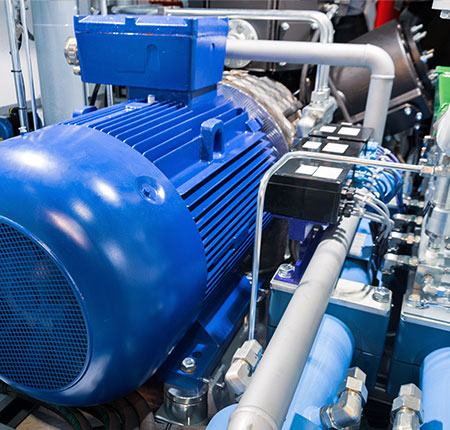

By using our technical skills and working with your staff or contractors, we identify which energy-using plant or areas should be measured. We interrogate the collected energy data and correlate it with other variables, such as production, to see where the problems and issues are. This process shines a light on many potential improvements, including:

By sharing your email address, you agree to our privacy policy.